R&d innovation

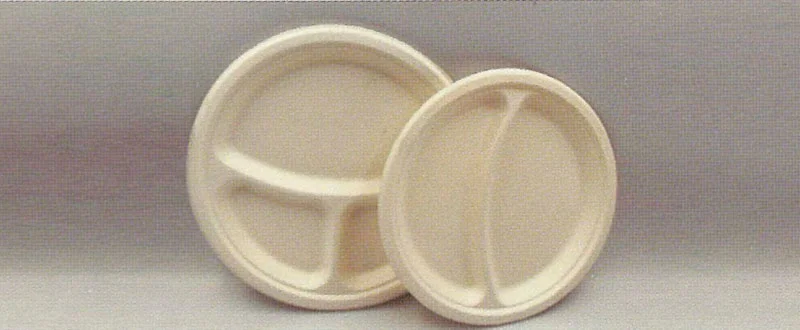

- Environmentally friendly and renewable: Using sugarcane bagasse as raw materials, the resources are renewable and widely sourced, reducing the dependence on non-renewable resources.

- Easily degradable: It degrades rapidly in the natural environment, reducing white pollution and conforming to the concept of environmental protection.

- High safety: The raw materials are natural, containing no harmful substances and being harmless to the human body.

- Good physical properties: It has certain strength, toughness and heat resistance, meeting the daily use requirements.

Product manufacturing proces

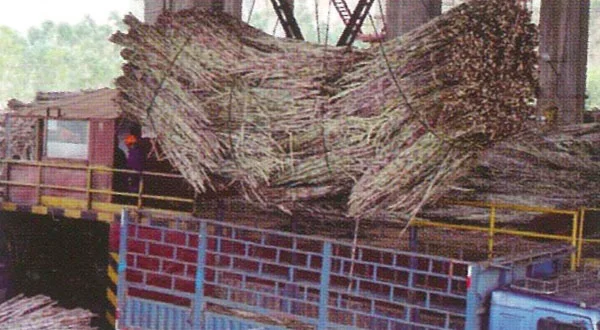

① Sugarcane

② Sugar Mills

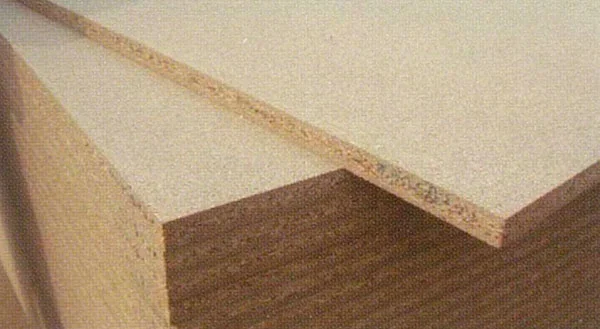

③ Bapasse Board

⑤ Compostable

④ Tablewares

Product degradation process

Open - air test:

Initial state

10 days

No significant changes

20 days

Slight decomposition

30 days

Slight decomposition

40 days

Partial decomposition

60 days

Partial decomposition

90 days

Partial decomposition

120 days

Severe decomposition

Landfill test:

Initial state

10 days

Decomposition occurs

20 days

Decomposition deepens

30 days

Decomposition deepens

40 days

Complete decomposition

Product characteristics and features

Use annual grass family discarded straw, the raw materials reproducible, needn’t use wood sources!

Under the natural status: completely degraded in 45 - 90 days, able to be family compost without pollution.

Waterproof and oil proof, able to be baked in oven, able to be heated in microwave oven, anti temperature up to 260℃.

Able to frozen and freeze storage, the lowest temperature able to be freeze -18℃ without deformation and osmosis.

Safety operation, not easily broken, convenient to transport and storage, more higher safety.

Overview of factory production

Internal R&D team

We firmly believe that advanced materials can bring fundamental changes to the world and human life. The company has expertise in biodegradable polymer materials, material synthesis and modification technology, clean energy, capital operation and other fields, to explore and develop innovative technologies and realize product applications for the current and future needs of the market.

Joint R&D Center

The company, together with the Research Institute of Tsinghua University in Shenzhen, Zhejiang University and Zhejiang University of Technology, has established a research and development force. Among them, the joint research and development center of the company with Zhejiang University and Quzhou Research Institute of Zhejiang University - Zhejiang High end Medical Polymer Materials Engineering Research Center was approved to be listed as Zhejiang Provincial Engineering Research Center in 2022, becoming one of the 12 research centers in the materials group.

The joint research and development center carries the advantages of all parties. Zhejiang University is supported by high-quality disciplinary resources led by academicians from the School of Chemical Engineering, and industrial amplification is provided by the Zhejiang University pilot base. The local government provides policy guidance, and Yuanjia Biotechnology conducts technological achievement transformation and commercial application of technological products.

R&D

Enterprises plan scientific research based on demand, drive industries with scientific research, integrate industrial capital, and promote scientific research with capital. They implement every scientific research project in a down-to-earth and efficient manner, ensuring to the greatest extent that "scientific research and development projects" are transformed into "successful innovative enterprises" Taking the PLA project as an example, the company has successfully and efficiently incubated scientific research achievements into high growth biotechnology companies, starting from "small-scale and pilot technology development → achievement transformation, industrial investment → introduction of listed company capital empowerment".

polymerization process optimization, by adjusting the type and amount of catalyst, material ratio and feeding method, polymerization temperature and other process conditions, the continuous preparation technology of PLA material with high molecular weight and narrow molecular weight distribution is realized.

polymerization process optimization, by adjusting the type and amount of catalyst, material ratio and feeding method, polymerization temperature and other process conditions, the continuous preparation technology of PLA material with high molecular weight and narrow molecular weight distribution is realized.

polymerization process optimization, by adjusting the type and amount of catalyst, material ratio and feeding method, polymerization temperature and other process conditions, the continuous preparation technology of PLA material with high molecular weight and narrow molecular weight distribution is realized.

*At present, the company is actively planning and developing other biodegradable green materials to expand various application scenarios of environmentally friendly materials.